- May 24, 2025

- Posted by: veeyor@dmin

- Category: Uncategorized

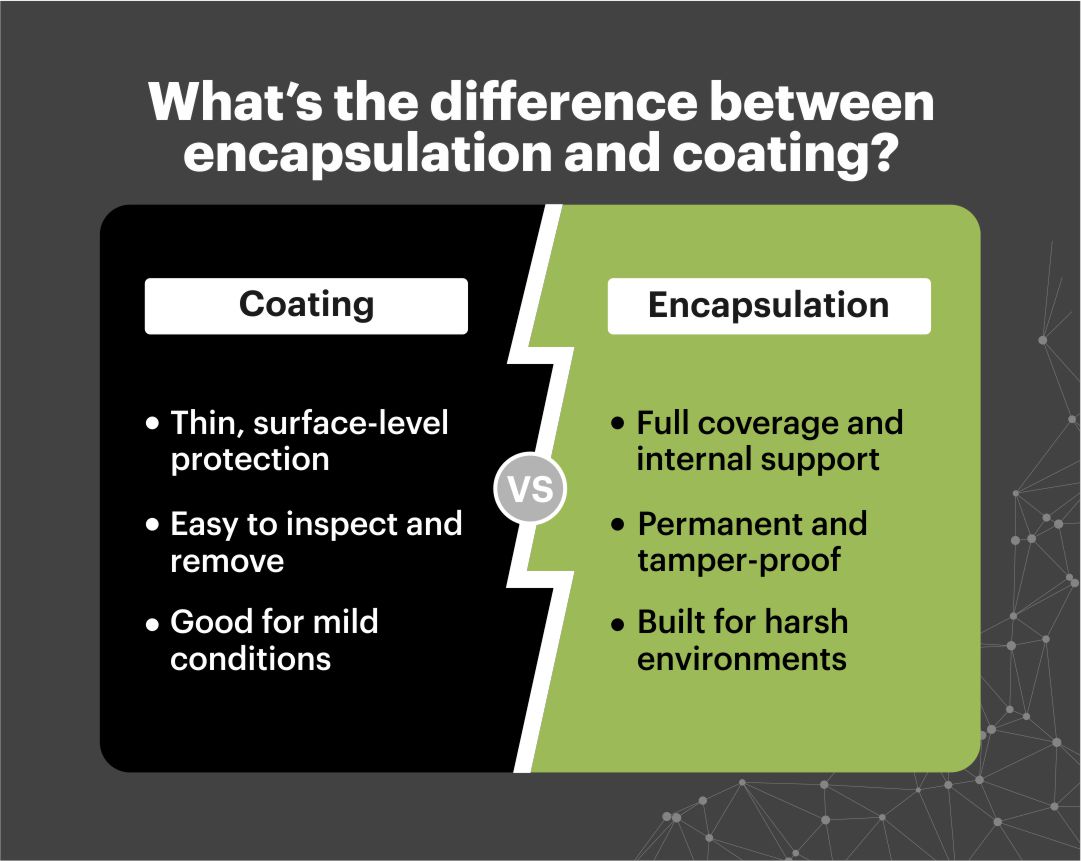

Understanding these two can help you avoid overdesign and underprotection.

You’ve probably heard both terms before.

Encapsulation. Coating.

They sound similar. Both involve covering something. Both are used for protection.

But what they actually do is very different.

If you’re working with electronics, filters, sensors, or circuit boards, it’s important to know when to use which because the wrong choice can either leave your component exposed, or make it harder (and more expensive) to repair later.

Coating: When you want a protective layer

Coating is a thin film that’s applied on the surface of a component.

It acts like a shield against moisture, dust, mild chemicals, or scratches.

- It’s usually just a few microns thick

- It doesn’t change the shape of the part

- And it’s often removable or reversible

Where it’s used:

Coatings are common in PCBs, wires, filters, connectors, and housings where some surface-level protection is enough.

Think of coating as putting on a rain jacket.

It protects the outside, but doesn’t lock anything in.

Encapsulation: When you want full protection

Encapsulation is more than just a layer.

It completely surrounds the component top, bottom, sides, even the gaps.

Once cured, the material becomes a solid mass that holds the part in place, protects it from shock, vibration, moisture, and even electrical interference.

- It’s thicker compared to coatings, often several mm

- The encapsulated part becomes non-accessible afterward

- It’s meant for harsh conditions or critical parts

Where it’s used:

Encapsulation is used in sensors, transformers, EV electronics, LEDs, or control units that face tough environments.

It’s like putting your component inside a safety box and sealing it shut.

Why this matters

Choosing between coating and encapsulation isn’t just technical; it affects cost, repairability, material usage, and long-term reliability.

At Veeyor, we’ve seen this first-hand:

Some customers needed just a simple moisture barrier, but were over-engineering with full encapsulation.

Others were using a basic coating for electronics that needed insulation and shock resistance. That’s why understanding this difference early saves time and prevents failure later. If you’re unsure which one better suits your product needs, ask us – we’re here for you..