- May 27, 2025

- Posted by: Mugdha

- Category: Uncategorized

Struggling With Flow Issues in Solar or Lighting Potting? You’re Not Alone

Potting and sealing in solar panels or LED lighting may look simple but on the shop floor, it’s anything but that.

You’re working with compact junction boxes, sensitive LED drivers, or long LED strips. And in every case, the potting material needs to:

- Flow smoothly

- Set at the right time

- Fill every gap without trapping air

- Handle heat, dust, and vibration over time

If it doesn’t, you’re left with slowdowns, rework, and field complaints.

Here’s a breakdown of where things typically go wrong, and what kind of material can actually help.

1. The Fill Isn’t Complete

Inconsistent flow means the potting doesn’t reach tight corners. Air gets trapped. You end up with uneven protection.

What you need: A compound that flows easily, stays workable long enough, and cures without pulling back.

2. The Cure Time Doesn’t Match Your Line

Some materials cure too fast: you barely start filling, and it’s already setting. Others take too long and block the next assembly step.

What you need: A material with a workable open time, and a predictable room-temperature cure.

3. The Material Doesn’t Suit the Application

What works for an LED strip won’t work for a junction box. What seals a headlamp might not manage heat in a driver.

What you need: Purpose-built materials not generic solutions.

How We Approach It At Veeyor

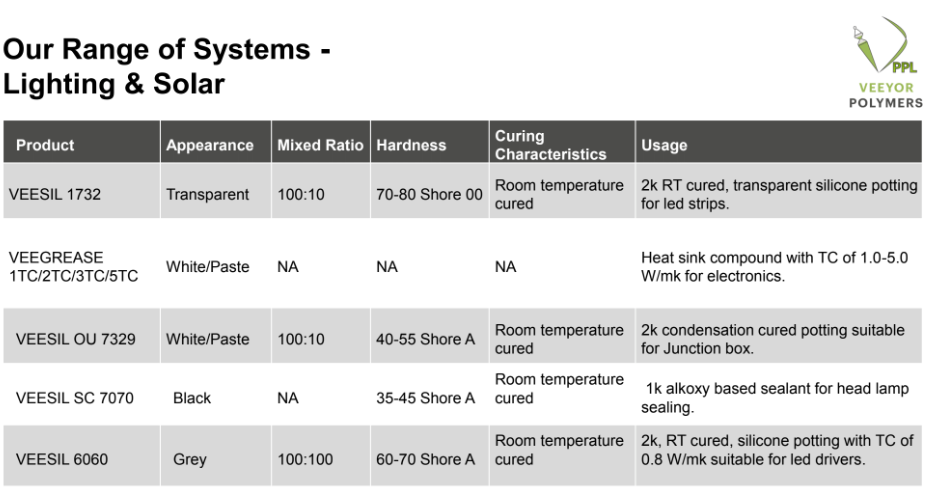

We don’t believe in “one compound fits all.” We’ve developed a specific range of potting and sealing systems for solar and lighting applications each tested for real manufacturing conditions.

If you’re facing issues with flow, cure, or performance

it’s not your process. It’s time to rethink the material.

Let us help you choose the right one.