Potting Compounds – A guide for selectors

- February 1, 2022

- Posted by: veeyor@dmin

- Category: Epoxy resins

A short guide to the selection of potting compounds

Potting and encapsulation compounds are critical components of sectors such as electronics. The compounds provide mechanical reinforcement to housed assemblies and protect the electronic circuits from exposure to moisture, mechanical shocks, chemicals, and vibration. Application of potting to electronic circuits also prevents corrosion and ensures a longer lifespan for electronic devices.

Benefits of potting compounds for electronic devices

- Thermal protection

Potting materials are good conductors of heat. Thus, they conduct the heat away from the circuits and reduce temperature stress on the electronic components.

- Resistance to environmental hazards

Compounds such as silicones offer resistance to UV, moisture, and ensure ozone stability. This enables electronic devices to be used in harsh environments.

- Fire protection

Potting compounds offer reliable fire protection. Materials compliant with the plastic flammability standard UL94-V0 do not ignite or maintain the fire. Silicone materials are self-extinguishing.

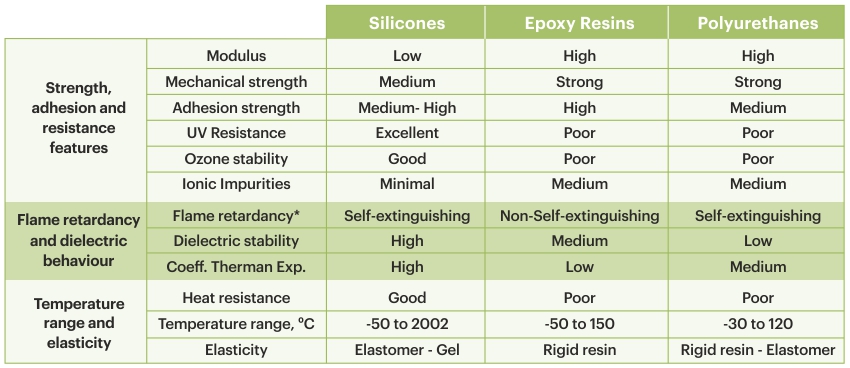

- A comparison of the three major compound groups

Potting compounds are classified into 3 major groups based on there ingredients and properties. Even though they are all used for potting and encapsulation, their properties and applications differ significantly.

Epoxy resins: Epoxy Resins are made from combining two components, Resin and the Hardener. Epoxies are special types of polymers containing molecules with repetitive subunits. This structure makes the resins highly durable and tough yet fairly elastic. Epoxies are the most widely used potting compounds in the industry.

Advantages of epoxy resins

- Have good adhesive properties

- Provide high electrical insulation

- Possess high mechanical strength

- Possess a high modulus

- High resistance to moisture and temperature

- High resistance to chemicals

Explore more about the benefits of epoxy resins on our blog here.

Polyurethane: Polyurethane (PU) resins are copolymers made up of isocyanate components and polyol. They possess high elasticity and display excellent adhesion to various substrates. Akin to epoxies, PU resins are made up of a base resin and a curing agent, but these resins are softer than epoxies.

Advantage of PU resins

- Possess high load-bearing capacity

- Are highly flexible

- Provide high resistance to abrasion

- High tensile properties and resistance to tearing

- Customizable flow and curing, including fast curing.

Silicones: Silicones compounds are a certain type of rubber. They require an additive platinum catalyzer to transition from the liquid to the solid state. Due to this makeup, these compounds cure rapidly even at room temperature.

Advantage of silicones

- Retains softness even at high temperatures (between -50 degrees C to over 200 degrees C)

- Possess excellent thermal conductivity

- Possess high flexibility

- Well suited for thermal cycling and thermal shock

A comparison of the three compound groups

Other key factors to be considered when selecting potting compounds

- Dispensing requirements

- Operating temperature of the device

- The desired hardness of the cured product

- The desired thermal conductivity

- Desired chemical resistance

- Cost of procurement

Veeyor’s Epoxy, PU and Silicone compounds are highly regarded for applications like potting of transformers, coil windings, capacitors, PCB components, filters, and many more…